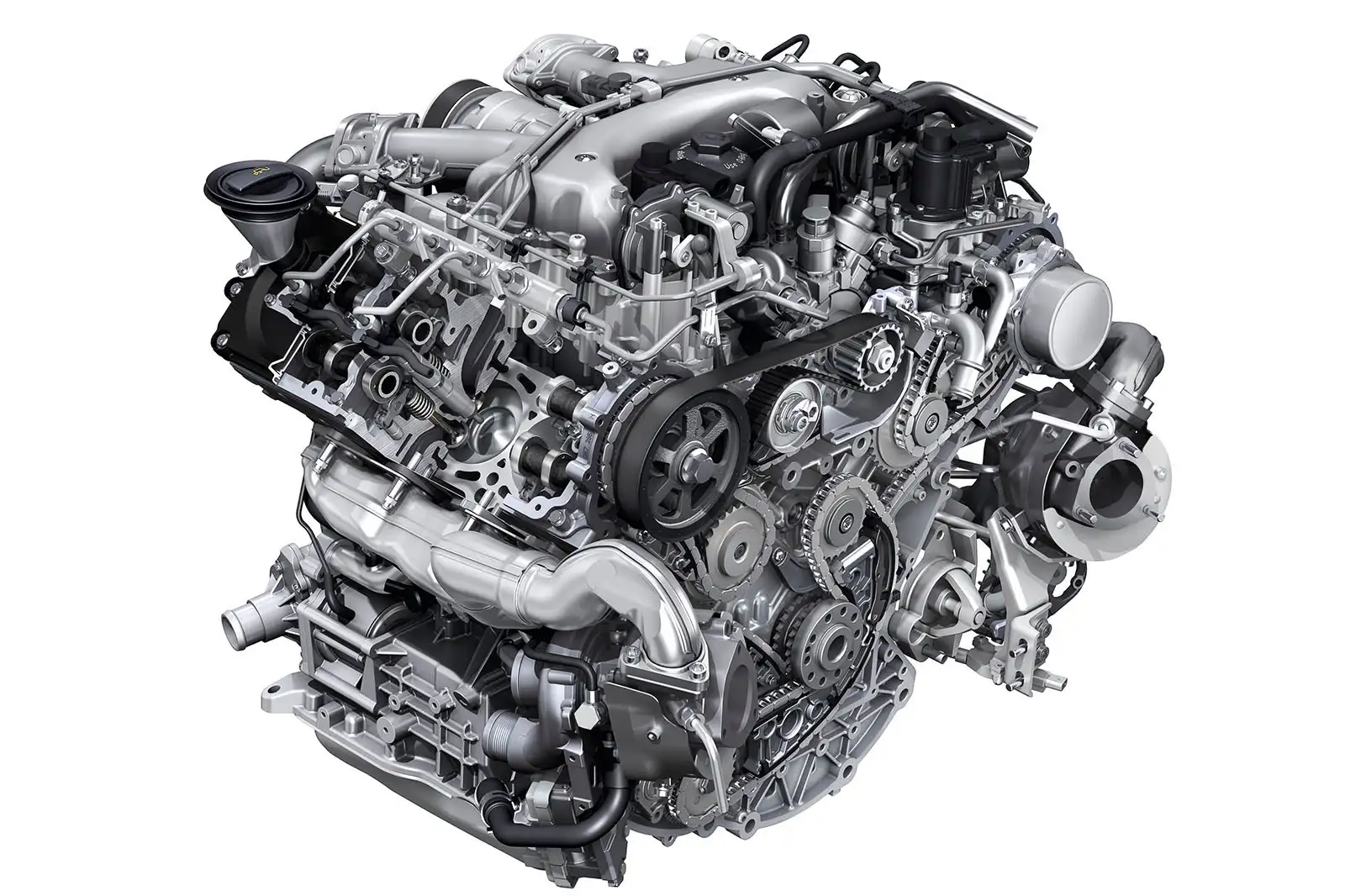

Understanding the Automotive Engine

The automotive engine has two main components: a crankshaft and a piston. The crankshaft rotates counter-clockwise to push the piston upward into the cylinder. The piston then moves half way up the cylinder, compressing the gas-air mixture. This process creates power, but it also reduces the effective compression pressure, which lowers the torque developed.

The automotive engine’s fuel is typically a volatile liquid, though it can also be a gas, such as natural gas or propane. Liquid fuels typically have the highest energy density per volume and can provide a long driving range. During normal operation, the fuel-air ratio is kept in a narrow range so that the engine produces the correct amount of torque. Throttling is a critical component of any combustion engine. When the load changes, the fuel flow rate must change accordingly.

Another type of automotive engine is a rotary engine. A rotary engine uses a single crankshaft in the middle of the engine and pistons that move in a star-like pattern. These engines are complex to understand, but they also produce more power. They are a good choice for bigger cars and trucks.

Advanced additives are also used to make engines more efficient. In addition to reducing friction, these additives help meet environmental and energy efficiency objectives. OEMs will look for ways to optimize fuel economy, but they should also consider longevity and reliability. These factors are important for vehicle owners, operators, and the environment. The performance of an engine’s components is also important, which can be increased by friction reduction.

The efficiency of an automotive engine depends on its design. Experimental engines have been measured to be 28% efficient, but most production engines are closer to 25% efficiency. Most vehicles on the highway have around 21% overall efficiency. The higher efficiency a vehicle has, the higher its fuel efficiency. So, it’s important to understand how to improve the efficiency of the engine in real-world conditions. The next step is to understand the dynamics of the vehicle.

One common modification involves milling the head of an engine. The milling process removes a fraction of an inch of metal from the lower side of the head. This reduces the volume of the engine from 6.3 to 5.3 cubic inches. The remainder of the volume equals 49.3 cubic inches. This is called the Compression Ratio.

The cooling system is another component that improves efficiency of an automotive engine. This is part of the cooling system and takes heat away from the cylinder walls and cylinder heads. In the 1970s, the productivity of an engine was only 15%, but today the engine is nearly 50% more efficient. By using unleaded gasoline, manufacturers have managed to lower carbon deposits and the risk of backfiring.

Another important component of an automotive engine is its layout. The layout of the cylinders may differ depending on the power and space requirements of a vehicle. Some engines have fewer cylinders, while others have more. Some engine configurations have three, four, or even eight cylinders.